Wednesday November 14, 2018

The quality of the work we do is something we take pride in here at FISHBIO, whether we are brewing beer, tending our garden, teaching children, and especially when we are monitoring fish. This includes making sure we have collected the most accurate data while in the field, have entered numbers correctly into databases, and have run analyses without any errors. For this reason, we spend a lot of time performing quality assurance and quality control, or “QA/QC” with everything we do. Quality assurance can be a daunting task since it involves making sure we have correctly identified, measured, and recorded information for thousands of fish per year. The fall can be an especially hectic time of year, as adult salmon return to our rivers from the ocean to spawn, which keeps us busy in the field. This means that our QA/QC “to do” binder quickly starts filling up, which keeps us busy back at the office too. Here’s a peek behind the scenes at what it takes to accurately document and successfully study Chinook salmon populations in our local rivers.

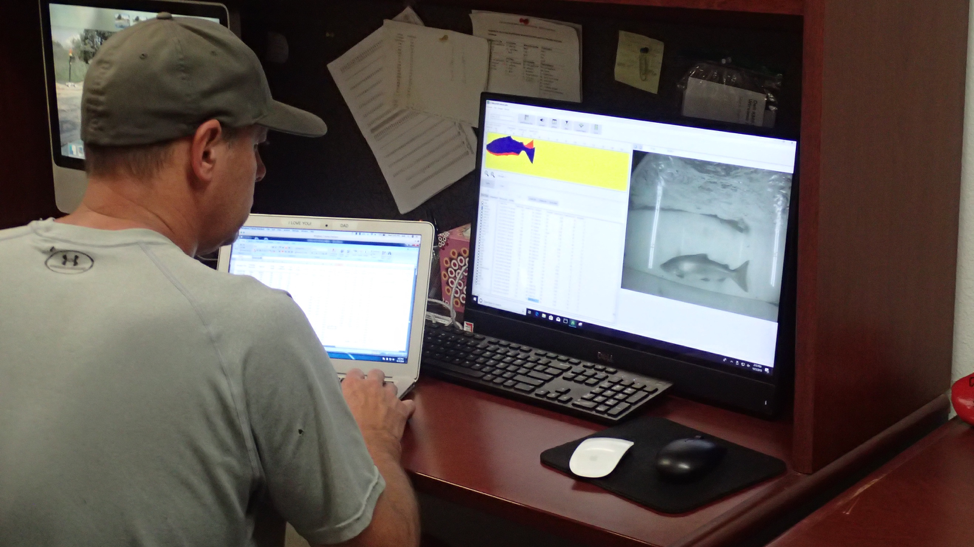

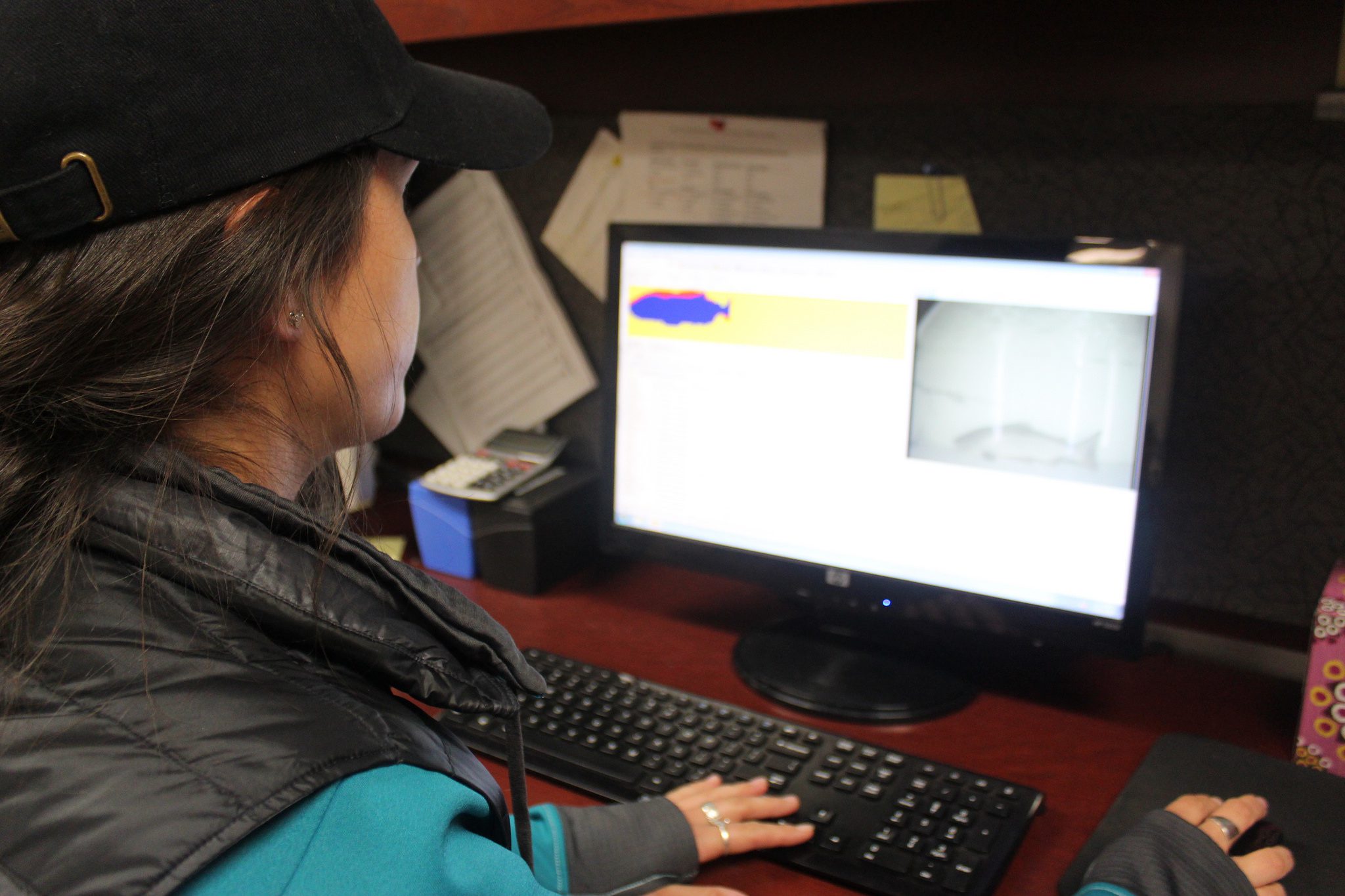

In order to monitor migrating adult salmon, we install portable resistance board weirs across the rivers before spawning season starts. The weirs are equipped with a Vaki Riverwatcher system that records infrared and video images of each fish as they swim upstream through the weir opening. Each day, our field technicians download data from the Riverwatcher to a flash drive and bring it back to the office along with a data sheet containing information on environmental conditions at the river that day, such as water temperature, turbidity, conductivity, and flow. The Riverwatcher saves us a lot of time by automatically counting and recording each fish passage and estimating its length. However, our biologists still have to review 10-second videos of every fish passage event to identify the species of fish and determine the sex of each salmon. After identifying up to 500 individual fish per day, entering the environmental data into databases, and sending out reports to clients, our work is still not finished. A different biologist or technician has to repeat the whole process to double check and make sure that the data was entered correctly. This QA/QC process, along with competent data collection and analysis, ensures that our biologists can write valuable and accurate scientific publications that can guide decisions about managing water and fish populations.

Although time consuming, QA/QC is an instrumental aspect of our work. Technology is constantly improving and making our jobs a little easier, though. When the Riverwatcher was developed, it freed us from having to manually scan continuous underwater footage to find fish passages. The next step in innovation will be technology that can identify fish on its own. Automated fish identification technology has been in development since 1990 (Strachan et al. 1990; Storbeck and Daan 2001; Hu, et al. 2012), but there are still challenges in applying these findings to real-world uses. Most of these automated fish ID systems use photographs of fish in-hand, not live fish that are swimming underwater. Their algorithms are created using a limited number of fish species from one specific location, and rely on major differences in fish shape or size (Hernández-Serna and Jiménez-Segura 2014), so the technology might not work everywhere, in changing conditions, or with fish that are similar-looking. The newest technologies being developed for automated fish classification utilize deep learning neural networks with refined algorithms (Li et al. 2015; Salman et al. 2016; Siddiqui et al. 2017; Sayed et al. 2018) Luckily, deep learning only gets better with more data, and fisheries biologists certainly have a lot of that, but there are still kinks to work out in teaching a computer to identify fish, such as “training” the software to identify species of interest. So the never-ending tasks of data entry and quality control ensure us good job security for now, but one day the apprentices we train may not be people, but computers.