Wednesday June 14, 2017

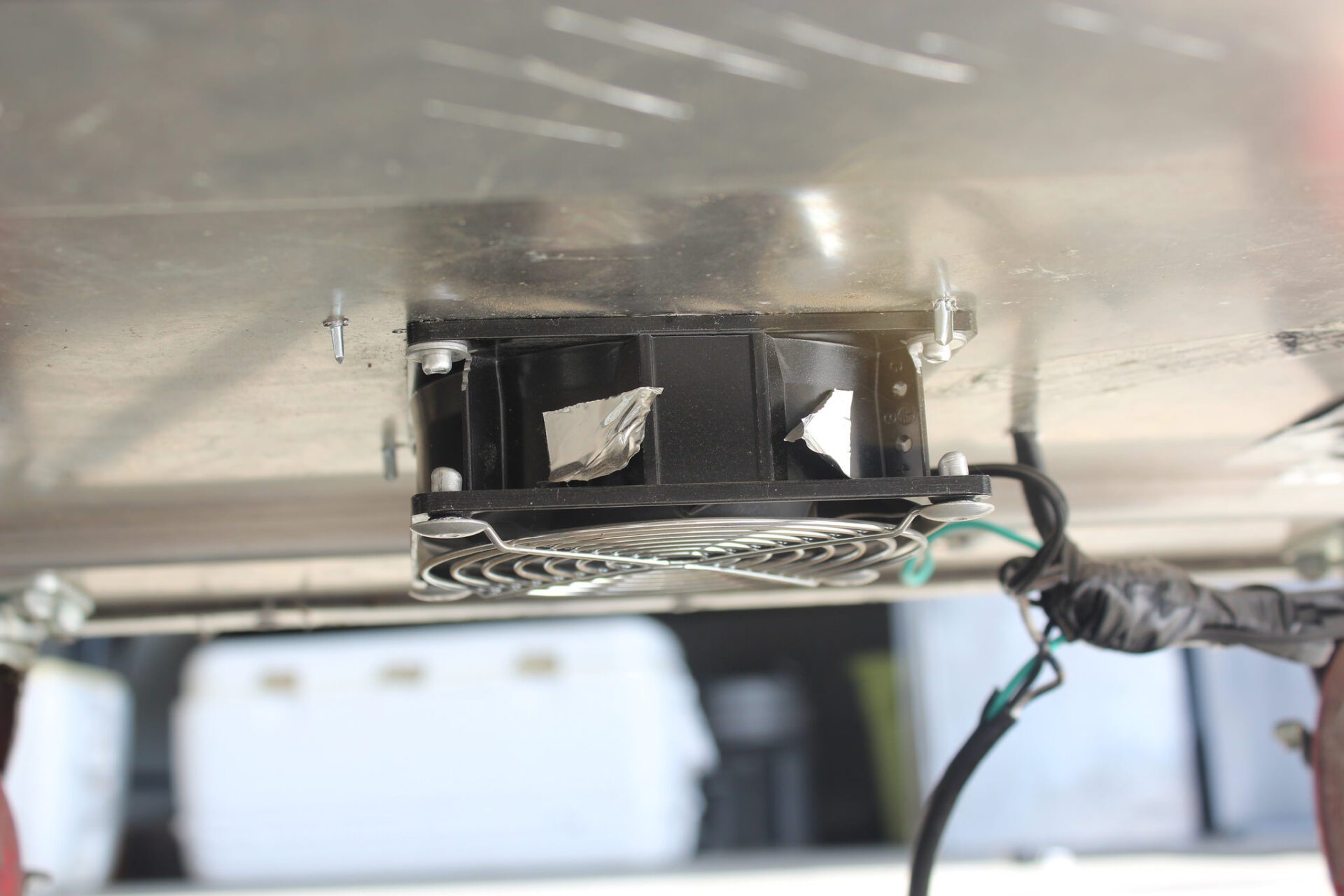

Thanks to the expert fabricators in our FABLAB, our kitchen now has a custom-built dehydrator, a bit larger than a typical off-the-shelf unit. They converted an inoperable bread proofer into a food dehydrator in a perfect example of upcycling. To make the dehydrator, they mounted an electric burner to the bottom of the chamber and wired it to a thermostat along with a temperature probe to precisely control the heat inside. A small fan was attached to the underside of the chamber to blow air over the burner and circulate heat throughout the dehydrator. An aluminum plate was also placed over the burner to evenly disperse the heat and avoid scorching food placed on the lowest shelf. Shelves were cut out of expanded aluminum sheets to allow for good air circulation around the fruit or veggies being dried.

This dehydrator got plenty of use last year after we harvested hundreds of peppers from the FISHBIO garden. After the peppers were dried, some were smoked and ground into powder to be blended into various seasoning blends like chipotle salt and a Peruvian chicken rub. The FISHBIO garden was planted again this spring with many of our favorite pepper varieties, so the dehydrator will get much more use when harvest time arrives. When it comes to the three R’s of the environment, we are always looking for creative ways to “reuse”!